NICKEL

Latest articles

Alloy X

Alloy X is one of the most widely used nickel base superalloys for gas turbine engine components. This solid solution strengthened grade has good strength and excellent oxidation resistance to 2000°F. Alloy X has excellent resistance to reducing and carburizing atmospheres, making it suitable for furnace components. Due to its high molybdenum content, Alloy X may be subject to catastrophic oxidation at 2200°F.

Alloy X is welded by all common methods such as gas tungsten arc, gas metal arc, shielded metal arc, electron beam and resistance welding. Use matching filler metal, keep interpass temperature low. After severe forming, fabrications may be annealed 2150°F, 15 minutes per 1/8″ of thickness, rapid air cool.

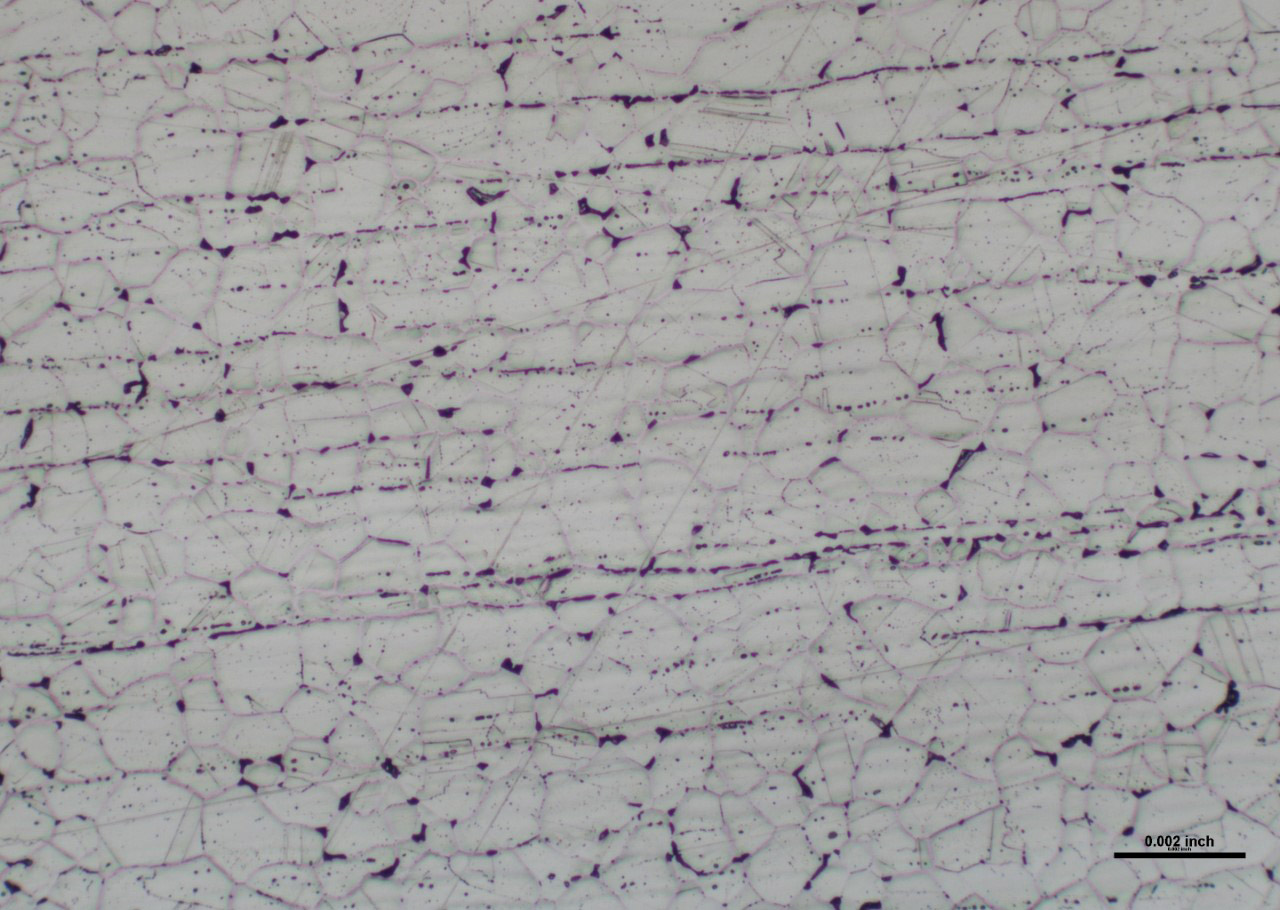

The levels of chromium, molybdenum and nitrogen in AL-6XN all serve to provide resistance to acidic oxidizing chloride solutions previously achieved only by the nickel base alloys. High nickel (24%) and molybdenum (6.3%) contents make AL-6XN a solution to chloride ion stress corrosion cracking. Because of its nitrogen content, AL-6XN has greater tensile strength than common austenitic stainlesses, while retaining high ductility and impact strength. The ASME allowable stresses for AL-6XN are up to 75% higher than for 316L stainless, and more than twice those for the copper-nickel alloys.

- Good high temperature strength

- Oxidation resistance through 2000°F

- Carburization resistant

Plate, Round Bar, Sheet

UNS: N06002

W. NR.: 2.4665

ASTM: B 435, B 572

ASME: SB 435, SB 572, SECT. IX P NO. 43, SECTION IX P NO. 43, SFA 5.14

AMS: 5536, 5754, 5798

GE: B50A436, B50T83, B50TF24

PDS: 1038 (X-LOW), 15102QFC

- Combustion liners

- Turbine exhaust components

- Aircraft cabin heaters

- Transition Ducts

Share This Page