STAINLESS STEEL

Latest Articles

PRODEC® 303

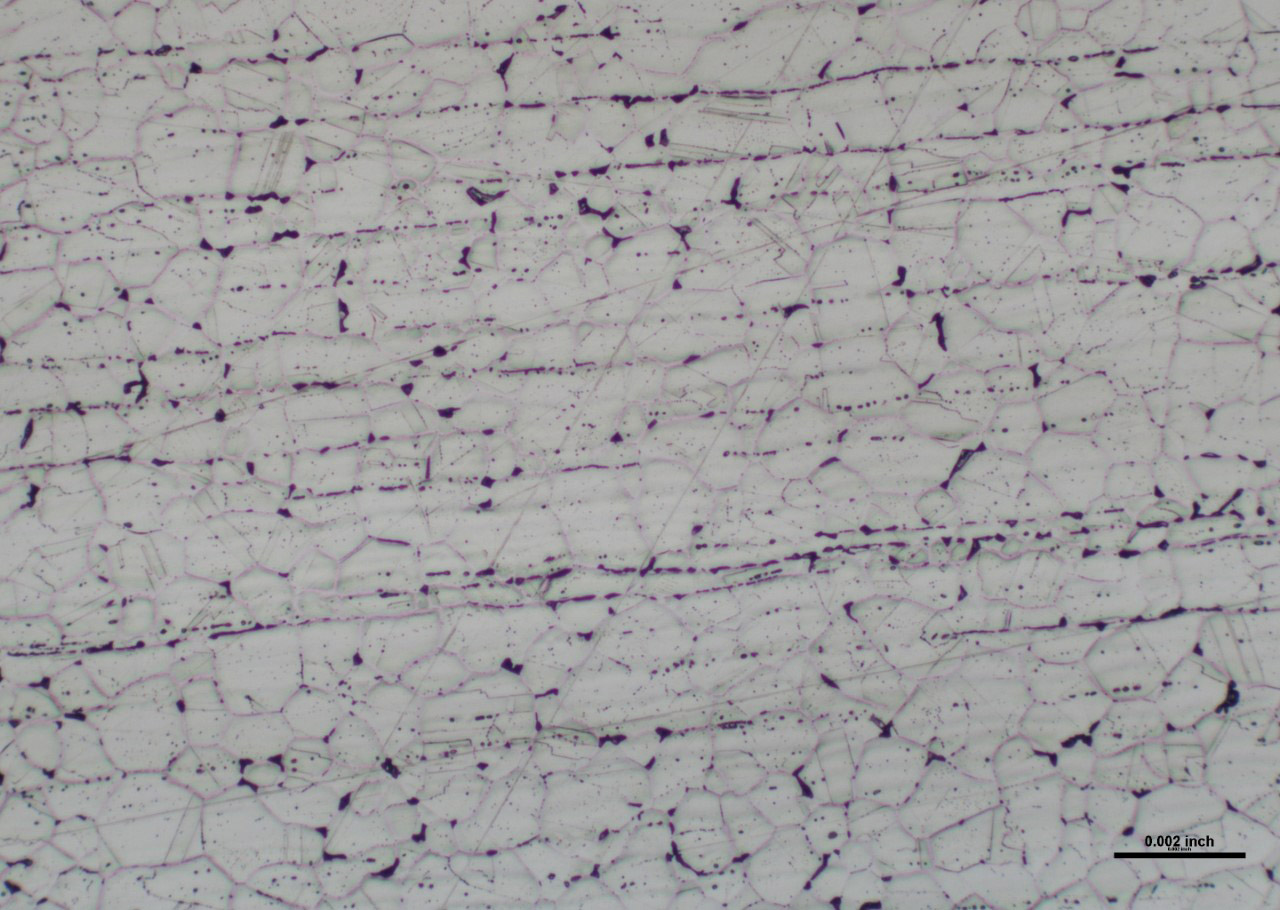

Rolled Alloys Machining Quality (PRODEC®) 303 is a fully resulfurized free-machining austenitic stainless steel melted and processed to maximize machinability. It should be considered for automatic screw machines where extensive machining is required. PRODEC® 303 is nonmagnetic in the annealed condition but may become slightly magnetic as a result of cold working.

PRODEC® 303 is resistant to mildly corrosive atmospheres but is inferior to 304 because of the high sulfur content. For optimum corrosion resistance, it is recommended that PRODEC® 303 be chemically treated to remove sulfides from the final surface of the parts.

The high sulfur content, added for machinability, is detrimental to hot workability. If hot forming is necessary, PRODEC® 304 or an intermediate sulfur level should be considered. When forging is necessary, it should be done in the 1800-2200°F range, and should be followed by annealing at 1900°F minimum and water quenching or rapid cooling by other means.The cold formability of PRODEC® 303 is limited by the sulfur content. Bending with a generous bend radius may be considered for PRODEC® 303. When cold forming is required, PRODEC® 304 should be considered.

PRODEC® 303 is not recommended for applications requiring welding. The high sulfur level in PRODEC® 303 makes it prone to weld solidification cracking. If welding is necessary, AWS E312 filler metal may be considered.

PRODEC® 303 is easily machined and produces small brittle chips. PRODEC® 303 may be machined at high speeds with deep cuts and heavy feeds on powerful, rigid equipment using good lubricants and sharp tooling.

- Melted and processed to maximize machinability

- Improved machinability over 304/304L and 316/316L

Hex Bar, Round Bar

UNS: S30300

W. NR.: 1.4305

ASTM: A 582

AMS: 5640

PRODEC® 303 Hex Bar, PRODEC® 303 Round Bar

- Automatic screw machines

Share This Page