STAINLESS STEEL

Latest Articles

PRODEC® 304/304L

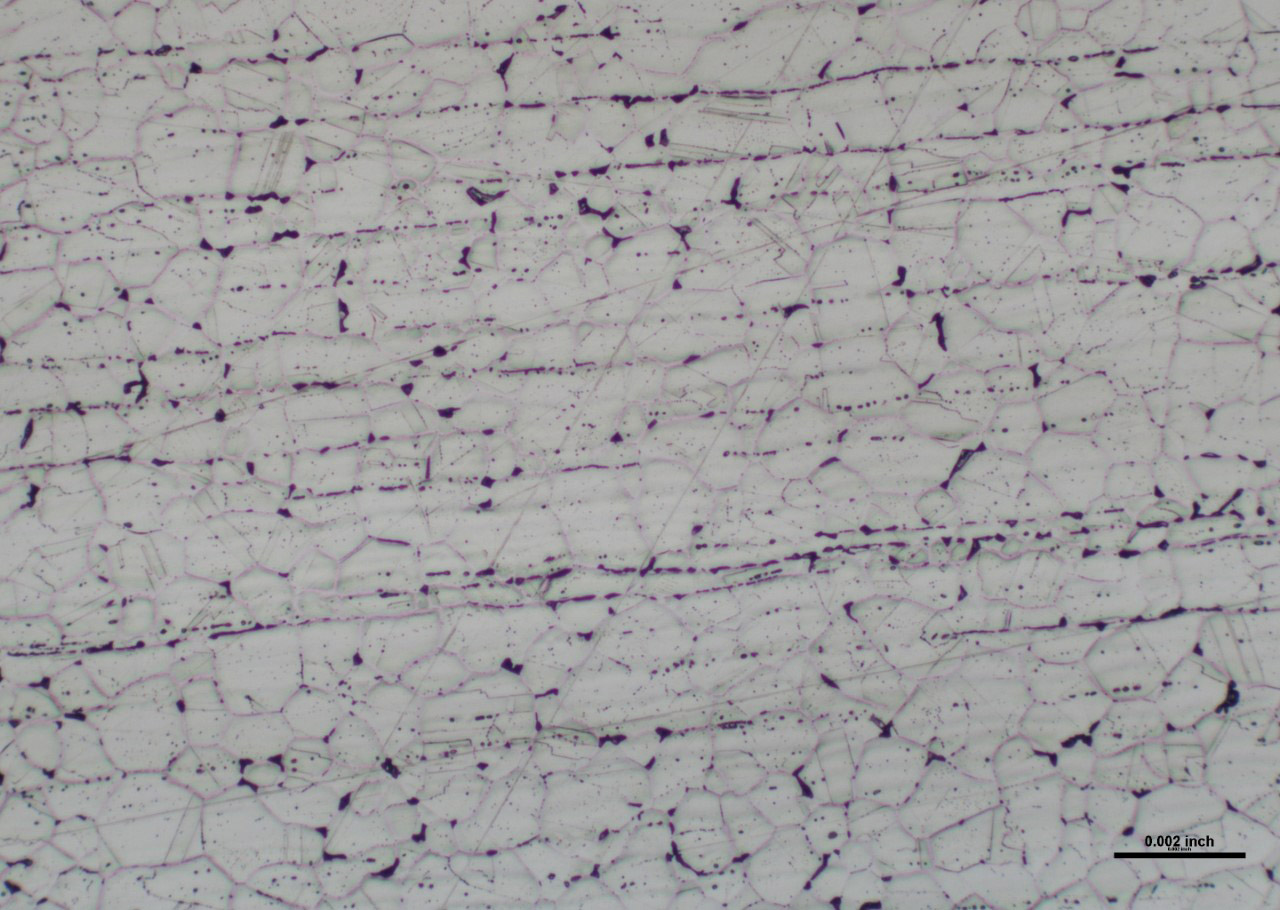

PRODEC® 304/304L is an improved version of standard 304/304L processed for improved machinability and outstanding uniformity. PRODEC® 304/304L offers faster machining speeds, longer tool life, improved part quality and lower total cost of machined parts. PRODEC® 304/304L is nonmagnetic in the annealed condition, but may become slightly magnetic as a result of cold working or welding.

Rolled Alloys Machining Quality (PRODEC®) 304/304L bar can increase yields and extend tool life to reduce machining costs. PRODEC® 304/304L is a versatile, general purpose stainless steel with good resistance to atmospheric corrosion, to many organic and inorganic chemicals, and to food and beverages. It has also been used in vacuum processing equipment and specialized instruments where high integrity is essential.

Although improvements in machinability in the past have been associated with reduced corrosion resistance, PRODEC® 304/304L has been shown to have corrosion resistance within the range typically expected to 304/304L stainless steel. Because of its low carbon content, PRODEC® 304/304L retains this corrosion resistance in the as-welded condition.

It is common for PRODEC® 304/304L to be dual certified as PRODEC® 304L and PRODEC® 304 when that material meets both the lower carbon limit of 304L and the slightly higher strength of 304. PRODEC® 304/304L is readily welded by full range of conventional welding procedures except oxyacetylene. AWS E308L/ ER308L filler metal should be used with PRODEC® 304/304L steel.

- Extended tooling life

- Reduce machining cost

Hex Bar, Round Bar

UNS: S30400, S30403

W. NR.: 1.4301, 1.4307

ASTM: A 240, A 276, A 312, A 479

AMS: 5511, 5513, 5639, 5647, QQ-S-763D

PRODEC® 304/304L Hex Bar, PRODEC® 304/304L Round Bar

- Chemical process equipment

- Food and beverage industry

Share This Page